ASME B89.7.1:2016 pdf download Guidelines for Addressing Measurement Uncertainty in the Development and Application of ASME B89 Standards

4 CALIBRATION AND VERIFICATION TESTING

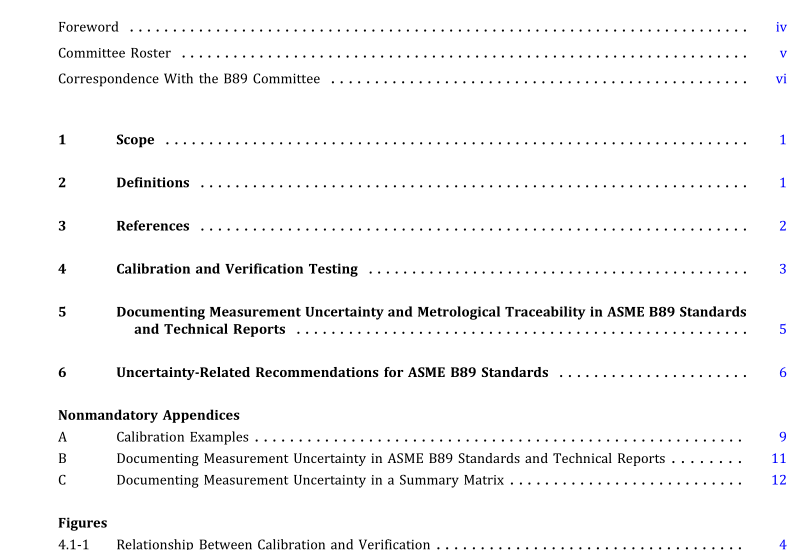

4.1 General The concepts of calibration and verification are not uniformly adopted across international and national metrology standards, and this often causes confusion, particularly in calibration practice. This Technical Report incorporates calibration and verification concepts from important standards such as JCGM 100, JCGM 200, ANSI/NCSL Z540.3, ISO 14978, and ISO/IEC 17025 to develop and apply a consistent approach for use with ASME B89 standards. The general relationship between calibration and verification is shown in Figure 4.1-1. Some calibration examples are shown in Nonmandatory Appendix A.

4.2 Calibration Measurements The measurements associated with the calibration process have one or more of the following purposes (see examples in Nonmandatory Appendix A): (a) They are used to determine reference values. (b) They are used to determine test values associated with a verification test. (c) They are used to determine necessary adjustments to measuring equipment.

4.3 Reference Value In dimensional metrology, reference values and the associated reference value uncertainties are usually reported on a certificate of calibration for the measuring equipment. A reference value and associated uncertainty are generally used to satisfy the second step in the defini- tion ofcalibration (see section 2), i.e., they are used in the subsequent measurement “to establish a relation for obtaining a measurement result from an indication.” In this manner, reference values are the output ofa calibra- tion that may be used as corrections when the calibrated measuring equipment is used on subsequent measure- ments. The corrections generally improve accuracy and reduce measurement uncertainty. EXAMPLE: For a gage block, the output of a calibration may involve measuring and assigning a reference value to the gage length, l g , as defined in ASME B89.1.9. This reference value is then applied as an input to the subsequent use of the gage block, which allows for more accurate use of the gage block than does using the nominal size and grade of the gage block alone.

4.4 Verification Test

4.4.1 Acceptance and Reverification Tests. Verification tests are used to establish that measuring equipment conforms to specified tolerance limits, e.g., MPEs. Therearetwotypesofverificationtests: acceptance tests and reverification tests. Acceptance tests are typi- cally used in the purchase process of measuring equip- ment, and the specifications are stated by the manufacturer. For reverification tests, the specifications are stated by the user and may or may not be the same as those used in the acceptance test.

4.4.2 Verification and Calibration. In many cases, particularly in the case of indicating measuring instru- ments, a verification test is completed and no reference values are assigned. For verification tests, the test values that are determined are not used as reference values and are not used to improve the accuracy of subsequent measurements using the measuring equipment; however, this does not preclude the verification test from being considered a calibration, as a verification test is a calibration ifit meets the requirements ofa cali- bration and is used as such. The results of a verification test, i.e., determination of compliance with specification, and the associated test uncertainty are generally used to satisfy the second step in the definition ofcalibration (see section 2). The use of verification tests as calibrations is common in dimensional metrology practice. EXAMPLE: For a gage block, the calibration may involve measurements to determine conformance to the specification for the limit deviation of any point from the nominal length, t e , as defined in ASME B89.1.9. The measured test values are used to determine conformance to specification but are not used to assign a reference value. In this manner, the nominal size of the calibrated gage block is used in subsequent measurements.

4.5 Adjustments JCGM 200 and ISO/IEC 17025 do not consider adjust- ments to measuring equipment part of a calibration; however, adjustments are often important to the calibra- tion process. This Technical Reportrecognizes the histor- ical use of the term calibration to indicate making