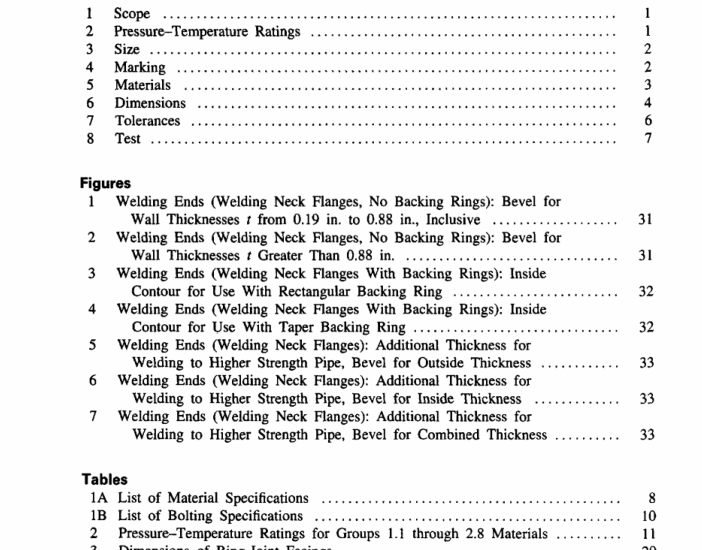

ASME B16.47:1996 pdf download LARGE DIAMETER STEELFLANGES NP8 28 Through NP8 60

1.10 Denotation

1.10.1 Pressure RatingDesignation. Class, followed by a dimensionless number, is the designation for pressure–temperature ratings (i.e., Class 75, Class 150, Class 300, Class 400, Class 600, Class 900).

1.10.2 Size. NPS, followed by a dimensionless number, is the designation for nominal flange size. NPS is related to the reference nominal diameter, DN, used in international and other standards. For the sizes cov- ered in this Standard, the relationship is DN p 25 .SPN؋ 2 PRESSURE–TEMPERATURE RATINGS

2.1 General Pressure–temperature ratings are maximum allow- able working gage pressures, in bar units, at the temper- atures in degrees Celsius shown in Tables 3 through 28 for the applicable material and class designation. Tables I-1 through I-26 of Mandatory Appendix I lists pressure–temperature ratings using pounds per square inch(psi) units forpressure atthe temperature indegrees Fahrenheit. For intermediate temperatures, linear interpolation is permitted. Interpolation between class desig- nations is not permitted.

2.2 Flanged Joints A flanged joint is composed of separate and independent, although interrelated, components: the flanges, the gasket, and the bolting, which are assembled by another influence, the assembler. Proper controls must be exer- cised in the selection and application for all of these elements to attain a joint that has acceptable leak tight- ness. Assembly and tightening techniques, such as con- trolled bolt tightening, are described in ASME PCC-1.

2.3 Ratings of Flanged Joints

2.3.1 Basis. Pressure–temperature ratings apply to flanged joints that conform to the limitations on bolting in para. 5.3 and on gaskets in para. 5.4, and that are made up in accordance with good practice for alignment and assembly (see para. 2.2). Use of these ratings for flanged joints not conforming to these limitations is the responsibility of the user. 2.3.2 Mixed Flanged Joints. If the two flanges in a flanged jointdo nothave the same pressure–temperature rating, the rating of the joint at any temperature is the lower of the two flange ratings at that temperature.

2.4 Rating Temperature The temperature shown for a corresponding pressure rating is the temperature of the pressure containing shell of the component. In general, this temperature is the same as that of the contained fluid. Use of a pressure rating corresponding to a temperature other than that 2 of the contained fluid is the responsibility of the user, subject to the requirements ofapplicable codes and regulations. For any temperature below −29°C (−20°F) the rating shall be no greater than the rating shown for −29°C (−20°F). See also para. 2.5.3.

2.5 Temperature Considerations

2.5.1 General. Use of flanges at either high or low temperatures shall take into consideration the risk of joint leakage due to forces and moments developed in the connected piping or equipment. Provisions in paras.

2.5.2 and 2.5.3 are included as advisory with the aim of lessening these risks. 2.5.2 High Temperature. Application at tempera- tures in the creep range will result in decreasing bolt loads as relaxation of flanges, bolts, and gaskets takes place. Flanged joints subjected to thermal gradients may likewise be subject to decreasing bolt loads. Decreased bolt loads diminish the capacity of the flanged joint to sustain loads effectively without leakage. At tempera- tures above 200°C (400°F) for Classes 75 and 150, and above 400°C (750°F) for other class designations, flanged joints may develop leakage problems unless care is taken to avoid imposing severe external loads and/or severe thermal gradients.

2.5.3 Low Temperature. Some of the materials listed in Tables 1 and 2, notably some carbon steels, may undergo a decrease in ductility when used at low tem- peratures to such an extent as to be unable to safely resist shock loading, sudden changes of stress, or high stress concentration. Some codes or regulations may require impact testing for applications even where tem- peratures are higher than −29°C (−20°F). When such requirements apply, it is the responsibility of the user to ensure these requirements are communicated to the manufacturer prior to the time of purchase.

2.6 System Pressure Testing Flanged joints may be subjected to system pressure tests at a pressure of 1.5 times the 38°C (100°F) rating rounded off to the next higher 1 bar (25 psi) increment. Testing at any higher pressure is the responsibility of the user, taking into account the requirements of the applicable code or regulation.

2.7 Welding Neck Flanges 2.7.1 Maximum Bore Size. Ratings for welding neck flanges covered by this Standard are based upon their hubs at the welding end having a thickness at least equal to that calculated for pipe having a 276 MPa (40,000 psi) specified minimum yield strength. To ensure adequate flange hub thickness for flange sizes NPS 26 and larger, the bore of a welding neck flange, dimension B as shown