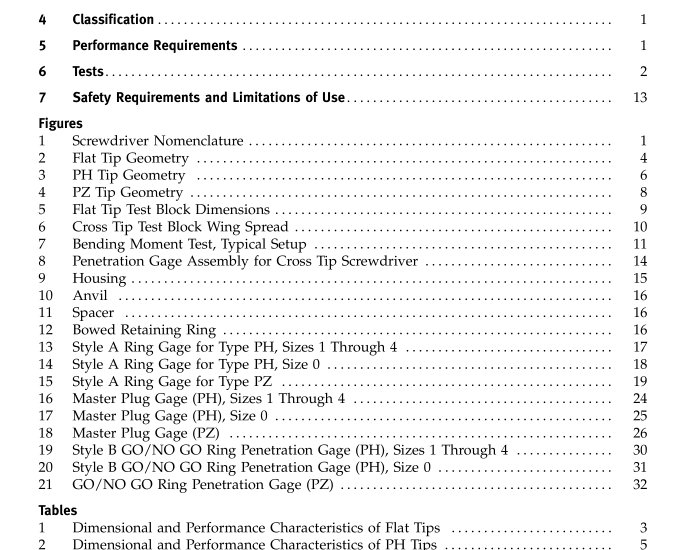

ASME B107.600:2016 pdf download Screwdrivers and Screwdriver Bits

Class 1 flat tips are for driving and removing slotted screws and shall conform to the dimensional and per- formance characteristics specified in Table 1 and Fig. 2. Taper at the tip shall be centered within 5 deg of the shank axis. Class 2 (PH) tips are for driving or removing screws with Phillips recesses and shall conform to the dimen- sional and performance characteristics specified in Table 2 and Fig. 3. Tip dimensions shall be gaged in accordance with paras. 6.8 and 6.9. Class 3 (PZ) tips are for driving or removing screws with Pozidriv recesses and shall conform to the dimen- sional and performance characteristics specified in Tables 3 and 4 and Fig. 4. Tip dimensions shall be gaged in accordance with paras. 6.8 and 6.9. 5.2 Materials The materials used inthe manufacture ofscrewdrivers and bits shall be suchas to produce products conforming to the requirements of this Standard.

5.3 Markings Screwdrivers and bits shall be marked in a plain and permanent manner with the manufacturer’s name or with a trademark of such known character that the man- ufacturer shall be readily determined. Marking shall be as permanent as the normal life expectancy ofthe screw- driver to which it is applied (providing the marked surface has not been subjected to a fretting or abrading action) and be capable of withstanding the cleaning pro- cedures normally experienced during its intended use.

5.4 Finish Metallic components of screwdrivers and bits shall be essentially free from scale, seams, laps, cracks, or any condition thatmay adversely affectdurability or service- ability of the tool. Screwdrivers and bits shall be treated in a manner to resist rust or corrosion. There shall be no evidence of peeling or chipping of any coating, where applicable.

5.5 Handle The handle shall be suitably finished to provide a comfortable grip. The handle shall be free from rough edges, sharp corners, or tool marks that affect comfort while using the tool. When the handle is furnished with a cushion grip, there shall be no detectable slippage between the handle and cushion grip under normal usage.

5.6 Hardness Type I screwdrivers’ tip portion or the entire blade shall be hardened to not less than 50 HRC. Type II bit tips (fora minimum distance oft 1 or L) shall be hardened to not less than 56 HRC. The rest of the bit shall be hardened to not less than 50 HRC. 6 TESTS WARNING: Many tests required herein are inherently hazard- ous, and adequate safeguards for personnel and property shall be employed in conducting such tests. These tests are designed to evaluate the tools and materials and do not condone the use of the tools in an environment, or in a manner, inconsistent with safe use of the tools.

6.1 Hardness Test The Rockwell hardness test shall be conducted in accordance with ASTM E18.

6.2 Tip Torsional Test The tip of each sample under test shall be fixtured in a test block of applicable dimensions shown in Table 1 and Fig. 5 (Class 1), Table 2 and Fig. 6 (Class 2), or Table 4 and Fig. 6 (Class 3). The test block shall have a hardness of not less than 60 HRC. When tested to the minimum tip torque value speci- fied, neither the shank nor the tip shall show visible permanent deformation. The torque shall be applied by forces acting perpendicular to the long axis ofthe blade/ bit with the tip held securely in the test block. It is permissible to support the blade/bit in a suitable posi- tion for test. The blade/bit shall be restricted from endwise movement during testing.

6.3 Assembly Torsional Test (Type I) The test shall be conducted after preheating the entire tool to a uniform temperature of 125°F ± 5°F. The torque shall be applied within 1 min after removing the tool from the heating medium. The torque shall be applied by forces acting at or near the middle of the natural grip of the handle perpendicular to the long axis of the grip with the tip held securely in the test block. It is permissi- ble to support the shank at or near the junction of the shank and handle in a suitable position for test. The screwdriver shall be restricted from endwise movement during testing. When tested to the minimum assembly torque value specified in Table 1, 2, or 4, the assembly