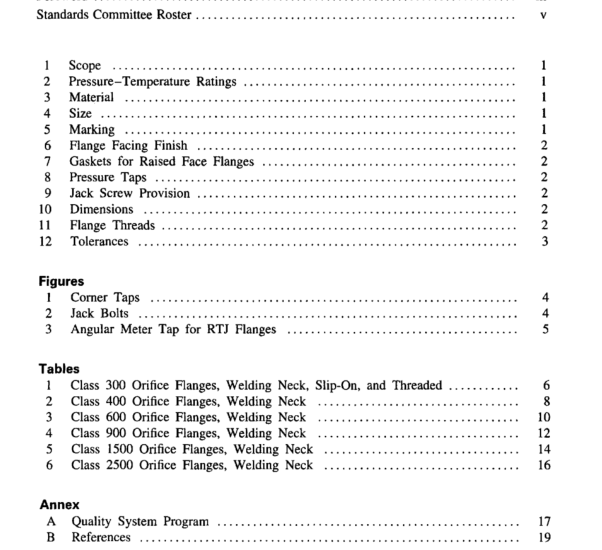

ASME B16.36:1996 pdf download ORIFICE LANCES

6 FLANGE FACING FINISH

The finish of contact faces shall conform to therequirements of ASME B16.S.

7GASKETS FOR RAISED FACE FLANGES7.1 Gasket Thickness

Flange dimensions are based on the use of 0.06 in.thick gaskets.1

7.2 Gasket Thickness

If gaskets of differing hardness and compressibilityare used, the rules of Annex E of ASME B16.5 shailgovern.

PRESSURE TAPS

8.1 General

Each orifice flange is provided with two pressuretap holes extending radially from the outside diameterof the flange to the inside diameter of the flange.Corner taps may be used on NPS 1/ and smaller ifspace perimits. See Fig. 1. For ring joint flanges listedin Tables 2 through 6, where radial taps will interferewith the ring groove,angular meter taps,as illustratedin Fig. 3,will be required. Each pressure tap hole shallbe equipped with a pipe plug.

8.2 Location

The 0.94 in. locating dimension for raised face and0.75 in. for ring jointT shall be measured at the bore.8.3 Pipe Connection

Unless otherwise specified,pressure tap holes maybe either tapped /NPT or h NPS socket connectionin accordance with AME B16.11.

9 JAcK SCREW PROVISION9.1 Location

Each flange shall have a machine bolt mounted ina hole drilled on the flange center line at 90 deg. fromthe pressure taps,for use as a jack screw. Machinebolt shall be regular with one heavy hex nut. See Fig. 2.9.2 Slot for Nut

A slot shall be provided in the flange 0.06 in. widerthan the width across flats of the nut. The depth ofthe slot shall admit the nut so that there is no interferencewith the joining of the flanges when bolted togetherwithout orifice plate.

9.3 Tapped Hole

As an alternative to para. 9.2.,a tapped hole maybe provided and the hex nut omitted when agreed onbetween the purchaser and the manufacturer.

10 DIMENSIONS

10.1 Flange Dimensions

Dimensions are listed in Tables 1,2,3、4.5,and 6.10.2 Gasket Dimensions

Gasket dimensions shall be in accordance with Ap-pendix E of ASME B16.5.

11 FLANGE THREADS

Threaded flanges shall have an American NationalStandard taper pipe thread conforming to ASMEB1.20.1.

a)The thread shall be concentric with the axis ofthe flange. Variations in alignment shall not exceed0.06 in./ft. (O.5%).

(b)The flanges are made with counterbores at theback of the flange and the threads shall be chamferedto the diameter of the counterbore atan angle ofapproximately 45 deg. with the axis of the thread toafford easy entrance in making a joint. The counterboreand chamfer shall be concentric with the thread.(c) In order to permit the pipe to be inserted to theface of the flange,the threads should have full rootdiameters through to the face of the flange,or shallhave a counterbore at the face of the flange.